Choosing the right paint hardener according to the context and type of repair will be essential to obtain an excellent final performance of the paint applied and a long lasting and quality repair.

In this post we show you all the aspects and tips to consider when choosing the paint hardener for your car’s bodywork that best suits each context and need.

What is a paint hardener and for what is it used?

A hardener, also known as paint hardener, is a chemical product that is added to paint (in 2-component products) to cause a chemical reaction that leads to hardening (polymerisation), without which the paint (e.g. a primer paint or clearcoat) would not dry.

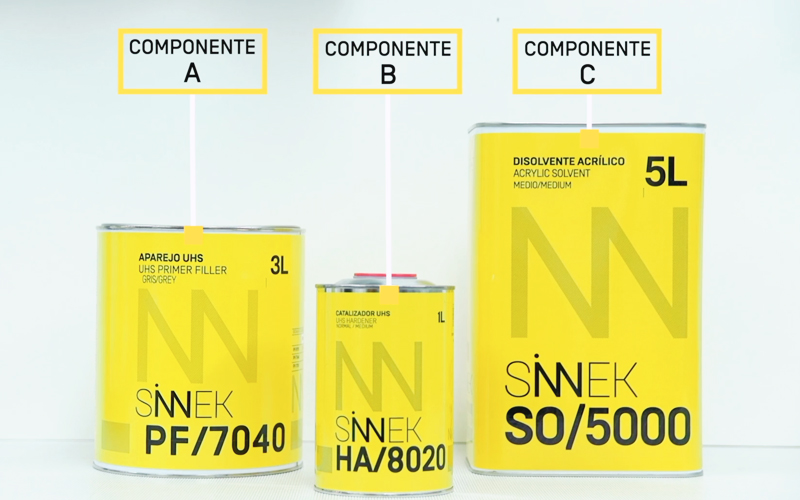

2K paints or 2-component paints are those that require a hardener for its their correct operation. Component A is the paint, such as the primer, putty or clearcoat, and component B is the hardener. Thinners would be component C of the mixture.

Importance of the paint hardener in the repair process

One sometimes tend to underestimate the role of hardeners and their correct use in the repair process in bodyshops, but an incorrect choice of hardener or its incorrect mixture is the cause of different paint defects.

The right choice of hardener allows us to improve our productivity

The right choice of hardener allows us to improve our productivity

As mentioned, the main function of a hardener is to increase the speed of a chemical reaction, in this case paint drying and hardening, preserving its nature once the reaction is complete.

In order to be productive in the repair, it is essential to rely on a wide range of high-quality hardeners that allow great adaptability of use through their combination with different types of products, such as primers or clearcoats.

This will make it simpler and easier to use reducing storage and increasing product rotation.

Types of hardeners in bodywork paint

Hardeners are divided into 4 groups according to their drying speed:

- Slow hardeners.

- Medium or standard hardeners.

- Fast hardeners.

- Ultra-fast hardeners.

Let us now look at the factors to consider when choosing the correct hardener for each type of repair.

Tips for choosing the right hardener depending on the repair

Considering different factors such as temperature, humidity, size of the repair, mixing ratio, or pot life of the product, will contribute to obtaining high quality finishes.

1. Temperature

Temperature is the most important factor to consider when choosing a hardener.

With a temperature ranging between 20ºC and 25ºC, we can use standard or medium hardeners. Always considering the context and type of application.

Low temperatures and high humidity = fast or ultra-fast hardeners

With low or very low temperatures we will use fast or extra fast drying hardeners, and with high temperatures, we will use slow hardeners, in order to keep the paint film open.

it is also important to consider the temperature of both the product and the substrate.

High temperatures and low humidity = slow hardeners

In this sense, it is important to accommodate the work areas so that both parts, product and the application process acquire the appropriate temperature to perform a correct repair.

2. Humidity

As for relative humidity, the ideal range of application will be between 55 and 65%.

With high humidity it is advisable to use slow hardeners, to prevent paint defects such as blooming or loss of gloss.

3. Repair size

The choice of one type of hardener or another will depend on the repair size or number of parts, and on whether the repair will be partial or on the entire vehicle.

This way, in smaller repairs, it may be advisable to use fast or even extra fast hardeners, thus reducing drying and processing times.

On the other hand, in large repairs, such as entire vehicles, we will opt for medium or slow hardeners, which give us more time to cover the entire surface, without significant differences in the drying.

4. Mixing ratio

Observing the right mixing ratio of hardener and product is critical to obtain a correct finish.

The mixing ratio will vary depending on the type of product and hardener. The specifications are indicated in the “Mixing ratio” section on the technical datasheet.

5. Pot-life

Another factor to consider is the pot life of the product.

The pot life of the product will vary depending on the type of hardener used. Thus, the faster the hardener, the less time we have from the time we prepare the mixture until we can apply it securely.

6. Productivity

One of the most important aspects in everyday practice at the bodyshop is increasing productivity.

With a correct choice of hardener, you can influence these aspects, provided that the conditions described above are appropriate.

The ultimate goal should always be to increase the flow rate in the booth

Thus, in repairs where given the room temperature and the size of the repair it is possible, it will be advisable to use fast or ultra-fast hardeners, which shorten the drying and hardening time of the paint film, thus increasing the flow of booth repairs.

Conclusion

Logically, the combination of the right hardener and products such as high-performance, high efficiency clearcoats and primers will be the perfect combination to increase productivity and profitability of the bodyshop.