In the bodyshop, colorimetry is one of the most important aspects to consider when it comes to improving the profitability of our business and providing a quality service to our customers.

The wide range of shades and colours currently used in refinish is a great challenge for professional bodyshops. There are many factors that can influence the perception of a colour, which can present subtle differences that make colour matching difficult in car paint.

Having the right products and tools, and a solid knowledge base of colorimetry will help us to successfully overcome any refinishing process.

We can define colorimetry as the science that is based on the study of colour, developing processes to measure qualitatively and quantitatively the perception of colour by people.

Colorimetry in paint allows measuring and combining different colours according to the requirements of a specific colour.

Colorimetry in the bodyshop is based on the set of methods and tools used to optimise the integration of colour into the repair

Extrapolating this definition to the bodyshop we can define it as the set of methods and techniques used to measure, adjust and optimise the colour of the repainted part or parts with respect to their adjacent parts.

That is to say, integrating the repaired part correctly without any colour differences being visible to the human eye.

What factors influence the perception of a vehicle’s colour?

People’s perception of colour is subjective. We perceive one type of colour or another based on the amount of light reflected and absorbed by a given object.

Colour is an instrument that is intrinsically associated with the design and aesthetics of a vehicle, which can directly influence its commercial success. This is the reason why all vehicle manufacturers invest heavily in their tintometric systems to develop new and sophisticated colours among their configuration offering.

As we know, it is usual for the colour code of a vehicle to have different “variants”, to cover small deviations in shade.

These variations can be caused by various factors such as the application method during the manufacturing process, substrate material, ambient temperature and humidity, etc.

To these variations, we must also add the subjective perception of the professional, depending on the illumination light, the plane of the part, the type of substrate, etc.

Let us look at certain factors that influence the perception of a vehicle’s colour:

Light source

Light is a type of energy that is transmitted as a wave through space and manifests itself in the form of radiation.

The wavelength is the unit of measurement that we will use to classify whether or not a given colour can be perceived by the human eye.

Therefore, the same colour may differ depending on whether it is observed in natural sunlight, artificial light in a booth, a light bulb, etc.

The wavelength is the unit of reading that we will use to classify whether a given colour will be perceived by the human eye

This phenomenon, which causes colour differences depending on the type of light that strikes the object, is called metamerism.

This effect usually occurs in the bodyshop when we observe a repaired part under artificial booth light, and the same part can be seen to have different shades when it is inspected under natural daylight.

This will result in differences in the colour matching of the part with respect to its adjacent parts, which will have an impact on the final quality of the repair. Hence the great importance of verifying the light source in the colorimetry of a vehicle.

Purpose

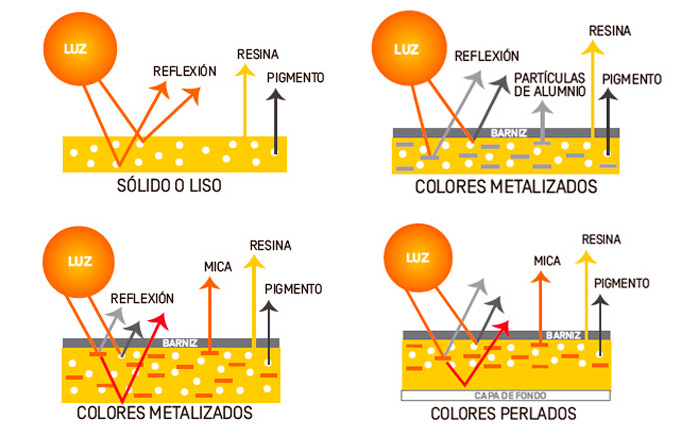

In the refinish sector, we consider the object to be the surface of the vehicle to be repainted or repaired. The type of colour we perceive from the vehicle will vary depending on the vehicle’s ability to absorb and reflect incoming light.

The greater the amount of light absorbed by the object, the lower the reflection capacity, so we will perceive a darker colour.

Thus, the type of finish of the part to be repaired (object) will directly influenceits absorption and reflection capacity. In a finish for example, having a rougher and more irregular surface, light is reflected in different directions, resulting in a lower perception of brightness and colour.

On the other hand, with glossy varnish finishes, light is reflected in the same direction in which it strikes the part, resulting in a higher level of brightness and colour to the human eye.

Human eye

Our human eyes visualise the object on which the light is absorbed and reflected and sends the colour perception obtained to our brain.

The human eye has mechanisms that allow it to differentiate between chromatic colours, achromatic colours or neutral colours, and the luminosity of the object.

Methods and tools for optimising colorimetry and colour matching in the bodyshop

The complication during the repair and repainting process begins when the colour of the surface to be repaired or its adjacent ones, present small differences in shade. This results in a wider range of colours to choose from, making the job of professional painters more difficult.

These slight variations can be caused by different factors:

- Colour differences produced during the car manufacturing process, due to the application system, layer thickness, different paint suppliers, etc.

- Diversity of variants of each paint manufacturer.

- Type of substrate material (plastic, steel, aluminium, carbon fibre, etc.).

- Highly complex colour reproduction of certain colours, such as complex three-coat colours.

- Application technique: each professional applies the product from a certain distance, movement or speed, which also results in slight colour variations.

- Incorrect preparation and mixing of the paint: sometimes it is the professional himself, who for not having followed the indications set out in the technical data sheet for the preparation of the paint, causes colour deviations.

Tooptimise colour matchingand integration of the repaired part into the bodywork, the bodyshop professional has a number of tools and methods at his disposal.

Tools for colour identification

Colour chart

The colour chart contains samples that are painted for each colour code and their respective variants.

Certain colour charts, such as in the case of SINNEK, are hand-painted and organised chromatically for a better and faster location of each colour code.

All SINNEK colour samples have been repainted by hand under the same conditions of speed, distance and number of coats

This significantly increases their reliability in terms of colour matching, as the colour samples show the actual paint applied under conditions like those in a bodyshop.

It must be considered that this system has a high cost for both the bodyshop and the manufacturer, since it requires constant updating in physical format of colour formulas.

Spectrophotometer

Without a doubt, the spectrophotometer is the most reliable tool for obtaining accurate information about a car’s colour code. The current trend is for this system to eventually replace the physical colour chart.

The spectrophotometer allows you to measure the wavelength of the exact colour it is measuring. From there, it provides the colour formula that best matches the surface colour.

The spectrophotometer is the most cost-effective and reliable option for the bodyshop

It should be noted that there may be cases in which the vehicle has been previously repainted. This is the reason why the colour reading may be closer to a variant than to the official formula itself.

The spectrophotometer, in combination with an extensive database of formulas and a powerful colour management software will allow the professional to instantly access almost any colour formula on the market, allowing for optimised colorimetry in the bodyshop.

Formula: spectrophotometer + database + management software + painter’s knowledge

As you can see, it is essential for the painter to know how the spectrum works and how to interpret the results it gives. Professionals with advanced knowledge of colorimetry may also make small colour adjustments, in what regards saturation, brightness or hue.

Methods used for colour testing

Professional painters have different methods available for optimising the colour matching and integration of the repaired part into the bodywork:

Application paint test cards

Another more rudimentary but highly effective method is applying the colour on test cards and then comparing their level of colour matching on the surface of the vehicle.

This process allows us to improve colorimetry and coverage of blending and patches, knowing with certainty the ideal number of coats to apply and maintaining similar application conditions, i.e. movement, speed or distance from the substrate.

The main disadvantage of this colour testing process lies in the time required to create different colour variants and number of coats (mixture preparation, application and drying times).

This is especially true in multi-brand bodyshops, where there is a large number of colour possibilities.

However, given its reliability, it will allow us to save repeating work and improve bodyshop productivity, especially in the repair of complex colours.

Light gun

A light gun is a particularly useful tool to verify colour matching and improve the colorimetry of a car.

Through the projection of a wavelength that is similar to natural day light, it allows us to better appreciate the different colour hues, and to detect possible defects such as marks from sanding, coverage or metamerism.

The light gun allows us to simulate different light conditions and intensities, optimising colour verification.

How to optimise colour matching in the bodyshop with a spectrophotometer

You must consider that the arrangement of the part on the body (vertical, horizontal, etc.) can cause the gloss reflected by the surface to vary.

Let us now look at an example of the use of a spectrophotometer to optimise the colorimetry of a repair in the bodyshop.

- Find out if the colour is original or repainted

First, we verify the vehicle’s colour code. In parallel, we examine the different parts and structure of the vehicle in detail to find out if it has been repainted, or if it has any finish defects.

A colour variant may be a better match than the official formula on a repainted part.

If blending, the colour reading will be taken from parts that are adjacent to the repair. If it is a patch repair, the reading may be made on the same part.

- Deep cleaning of the surface

Degrease and polish the surface with a machine finishing polish to obtain a more accurate and interference-free colour verification.

- Spectrophotometer calibration

It is advisable to calibrate the spectrum daily to obtain more accurate colour information. It must be borne in mind that an inadequate substrate temperature may cause a decalibration of the spectrum.

- Special attention to effect colours

In special colours that have a high reflection, always take precautions to optimise their matching.

- Choice of the variant in the colour software

Once the reading has been taken, verify in the colour software the variant that best fits the information collected.

- Test cards – Opacity and Matching Test

Once you have chosen the variant, apply the paint on different test cards to verify its evenness on the surface.

- Repair by blending

Finally, we always recommend its application using a blending technique to ensure proper colour integration and matching in the bodywork.

Conclusion

As we have seen, the professional painter in the bodyshop has tools and methods that will help achieve a repair where the colour differences are imperceptible to the customer’s eyes. The experience and knowledge of the professional should do the rest.

However, having a quality premium paint with SINNEK’s W6000 Series will certainly be an added advantage to consider for excellent colour matching and coverage.