Matte clearcoats are becoming increasingly popular as users search forexclusive bodywork aestheticsthat set their vehicles apart. A matte finish is oneway of personalising a vehicle; it is obtained by finishing with a matte clearcoat, which gives the surface a silky, elegant appearance.

Traditionally, matte paint was only used on high-end vehicles or small body parts such as mouldings, handles, mirrors, etc. However, as with three-coat colours, today many vehicle segments offermatte finishesas part of their optional extras.

That is why we at SINNEK ACADEMY thought it would be interesting to provide bodywork and paint-shop professionals with up-to-date and detailed information on vehicle repairs using this type of topcoat.

What is matte paint or paint with no sheen?

As we’ve just said, some paints achieve matte finishes by using a special low-gloss clearcoat, known as a matte clearcoat.

This type of clearcoat gives the surface a micro-rough finish, whichprevents the full passage of light, causing it to reflect in various directions and reducing the sheen and the reflected light.

Matte clearcoat gives the surface a micro-rough finish, reducing the sheen.

An excellent option of this kind of clearcoat is SINNEK’s CC/1764 matte clearcoat, a high-solids matte clearcoatwith outstanding resistance to scratching and contact with hydrocarbons. It is easy to apply, performs well outdoors and gives a smooth finish.

How to know which gloss level to apply with matte clearcoat?

To get the best repair results using matte clearcoat in your bodywork and paint shop, you need to take into account several important things that affect the final application of clearcoat.

Nowadays, partly due to the increasing number of vehicles with this type of finish, manufacturers have been forced to provide bodywork and paint shops with special clearcoats for several types of finishes: matte clearcoat, satin clearcoat or gloss clearcoat.

Depending on the sheen required for a correct repair, the painter can vary the clearcoat mixture to obtain the matching degree and type of sheen.

A good way of ascertaining the level of glossy or matte finish to apply to the surface is to prepare various matte clearcoat mixtures, each with a different proportion of satin or gloss clearcoat.

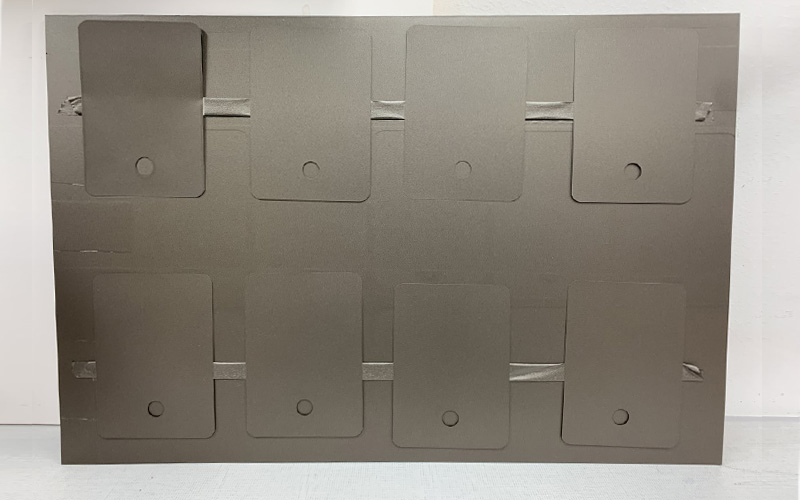

A recommended practice will be to prepare paint test cards to find out which clear coat mixture matches best in terms of gloss, colour and texture

Then, we prepare paint sample-panels to see which clearcoat mixture best matches the gloss, colour and texture of the original finish.

We then apply each mixture to a sample panel and compare them with the surface to be repaired to see which one best matches the glossy finish.

If you save the tests, you canalways use them in future repairs, and avoid repeating this process.

There is also a tool, called the gloss meter, which has been specially designed to measure the gloss level required for a clear coated or polished surface.

However, this tool is not commonly used in bodywork and paint shops. Specialised centres who customarily work with this type of matte finish may be more familiar with it.

How to apply matte clearcoat: 9 essential tips

As in many other cases, to achieve a correct matte finish in a repair we must follow the manufacturer’s instructionsin the product’s technical data sheet.

Obtaining the same gloss level of the part to be repaired as its adjacent parts is one of major difficulties in repainting this type of finish.

Several factors will determine whether yourrepair is successful and blends the matte-finished parts into the surrounding ones:

1. Uniform mixing of the matte clearcoat

The matte clearcoat must be thoroughlyblendedand the combination of clearcoats to be used must be uniformly mixed, since this will directly influence the level of sheen achieved after the application.

2. Precise amount of hardener and thinner in the mixture

Add the precise amount of hardener to the mixture, followingthe instructions in product’s technical data sheet.

Too much hardener will increase the final gloss. Similarly, too little may reduce the sheen of the clearcoat.

Use the same hardener in the repair that you prepared for the tests (do not use fast hardeners or thinners since accelerated drying processes can lead to surface irregularities).

Similarly, over-dilutingmatte clearcoat may make the coat too thin, which will also reduce the final surface gloss.

3. Matte clearcoat application technique

Apply a uniform coat of matte clearcoat, trying to avoid cloudiness. Application factors such as the speed and movement of each stroke, the distance between the gun and the part,and the spray-equipment settings will affect the final gloss level.

It is preferable to avoid overlapping, which may apply too much paint or thicker lays to some areas.

4. Prior cleaning of the surface

Dust or dirt particles are a great nuisance to painters. A poorly maintained ventilation system in the booth, or badlycleaned surfacewill probably cause the small specks and flaws to appear in the finish.

Matte surfaces cannot be polished sinceit would change the gloss level.

Unlike on glossy clearcoat finishes, you cannot use a polishing tool to remove these flaws, as polishing affects the gloss.

It is important that adjacent parts do not have any overspray (from painting), remains of adhesives (masking) or surface particles (specks, sags) as removing them by polishing would alter the gloss in these areas.

5. Applying matte clearcoat on the entire part (no blending)

It is not advisable to try and blend the clearcoat into the adjacent areas, as this may alter the thickness of the clearcoat.

We can try to blend in a repair by polishingthe clearcoat, but again this will change the degree of surface gloss. This is whymatte clearcoat must be applied to the entire part.

6. Different colour types have different gloss levels

It can be difficult to get the right gloss level when repairing light metallic and pearlescenthues, such as silver, gold or champagne, so morecare is needed when working with these special colours.

7. Differences in gloss level depending on the type and orientation of the part

The reflected gloss will vary depending on how the part is placed in the bodywork (vertically, horizontally, etc.).

To achieve a uniform sheen, test the clearcoat first using a paint test panel painted in the desired colour and placed in the same direction as the part to be resprayed.

The level of reflected gloss may vary depending on how the part is positioned (vertically, horizontally, etc.).

8. Influence of coating thickness on matte clearcoat

An excessively thick matte clearcoat will give a glossier surface (ideally the coat should be around 50 microns thick).

9. Drying method

Adhering to the evaporation time of the matte clearcoat between applying coats is essential to obtain a good finish. Make sure the matte finish looks right before starting to dry the part.

Moreover, booth drying will provide a glossierfinish than air drying.

Care and maintenance of matte paint

Given matte paint’s characteristics, greater care and maintenance will be required than with gloss paint finishes.

Matte-finished surfacesare mechanically weaker. Although you may not think so, scratches and small marks will be much more visible on matte finishes than they are on gloss finishes (and you cannot polish the surface to remove them).

Matte finishes provide the surface with less chemical and mechanical resistance.

It is also advisable to be extremely careful with some bodyworkparts such as door handles and footrests. Gentle but continuous rubbing on the same area can increase their sheen.

Matte finishes are also less resistant to chemicals, so fuel spills, or grease or oil must be cleaned off quickly to prevent their damaging the surface.

It is better to handwash the vehicle rather than take it the car wash, as the rollers and detergents may damage the matte finish.

Use specific products and tools for matte finishes, avoid abrasive products, polishes and waxes that can degrade and decrease the surface sheen.

Conclusion

As we have seen, we must take all these factors into account when applying matte paint, if we want to correctlyblend the part into the bodywork, which is the main challenge in this type of repair.

Despitetheir aesthetic appeal, the characteristics of matte finishes mean that wemust be extremely careful during the entire work processif we want to achieve a repair with a top-quality finish.