Today, metallic paints are one of the most used types of car paint both by manufacturers, with a wide catalogue of metallic and pearl colours, and by users, who seek to provide a differential look to their vehicles.

Many years ago, the development of innovative acrylic enamels allowed for great progress in the field of automotive colorimetry.

This was the root cause that favoured the emergence of new formulas and types of colours, with metallic colours standing out among them all.

Practically all cars that are manufactured today can be customised in metallic colours.

This great variety of colours increased especially with the arrival to the refinish sector of basecoat finishes , pushing to the background the mostly used single stage finishes.

The increase in metallic colours coincided with the arrival of basecoat finishes to the refinish sector

What is metallic car paint?

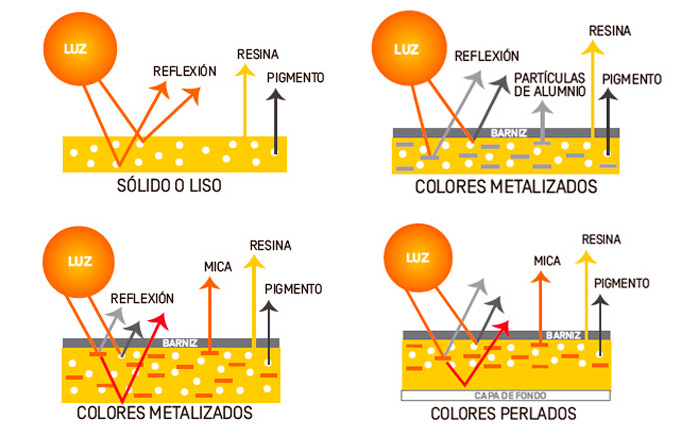

Metallic paint, also known as polychromatic, is a type of paint that has been added small aluminium particles or other metals in order to produce a shiny effect and depth to the surface, especially emphasised in bodywork contours.

The type, amount, size and colour of the particles can vary to produce all kinds of effects, gloss and reflections, providing a glossier finish than any solid paint.

This type of paint usually has a wide range of shades and colours, and its characteristic gloss is produced with the reflection of light on the tiny aluminium particles that are mixed with the paint. These particles capture light and reflect it.

The type, amount, size and colour of the particles can vary in order to produce all kinds of effects, shines and reflections.

The successive coats of the finish paint highlight this gloss and depth effect. Metallic colours are integrated in basecoat or three-coat systems, and require a final clearcoat coat to ensure sealing and protectionof the surface.

Advantages and disadvantages of metallic paint

One of the main advantages of metallic paint is that it provides a light protection against small damages and against discolouration caused by UV rays.

The colour variations produced by some metallic colours make it easier to conceal small defects. On the other hand, in solid colours, dents, scratches and other small damages are more visible.

Metallic paint also has an aesthetic function. It beautifies the surface by enhancing vehicle contours and lines, providing effects, brightness and luminosity and a selection of colour customisation.

In short, metallic paint significantly increases a vehicle’s visual appeal and its market value.

Metallic paint helps to enhance the contours and lines of the bodywork

Its most common disadvantage are its cost. Solid colours make vehicles more expensive, as a result of a more expensive and elaborate manufacturing and application process.

For the professional painter, reproducing some metallic colours also entails greater complexity and difficulty in matching the colours. Also, more time will be required for the repair.

Which pigments are used in metallic paint?

Metallic car paint can be classified depending on the type of pigments and particles it is composed of.

Metal pigments

These types of pigments are the most common in metallic paint.

They are composed of small aluminium particles, which are responsible for providing the shiny metallic lustre effect. They are usually mixed with absorption pigments (somewhat transparent to improve the gloss and depth effect).

They can also be mixed with other types of particles such as mica for improved reflection effects. The metallic particles of these pigments come in different sizes and shapes:

- Lenticular aluminium: this is a type of particle that has an oval shape, and a varying size. Lenticular aluminium can be thin, medium and thick. Due to its shape, the correct direction and coupling of this type of particles during repainting will be essential for a final flawless finish.

- Irregular aluminium: this type of aluminium has different shapes with more irregular edges and different sizes (extra thin, thin, medium, thick and extra thick). Its application and direction is usually simpler than that of lenticular aluminium.

These differences in shape and size, and the direction of the particles during application, will determine the type of effect obtained.

This is why certain metallic colours have different gloss and shades depending on the angle from which you look at the surface. This is the so-called “flop effect.”

Some metallic colours include a flop control in their formulation to reduce this effect.

Thin aluminium particles are matt and less problematic than coarse aluminium particles, which are glossy and reflect more light. Therefore, colours with a high percentage of coarse aluminium pigments will have a greater “flop effect”.

Pearl pigments

Pearl pigments contain different shapes and sizes of small particles or scales of the mica ore.

These particles are mixed with translucent pigments, which means low opacity. They cannot be applied at the bodyshop without first being mixed with a solid or metallic colour.

The pearly glow of pearl colours is due to the ceramic crystals in the paint which are responsible for reflecting and refracting light.

This reflection and refraction of light gives the colour a gloss and depth that is difficult to match even for colours with metallic pigments. Under bright light, the lighter shades become iridescent, producing different colours and shades from various angles, with very striking results. Pearl car paints are even more prone to small paint marks and defects than paints with metallic pigments.

Special pigments

These types of pigments provide an even sharper visual effect than metallic or pearl pigments.

Their use and application is not very common in the bodywork sector. They are more used in bodywork customisation.

When painting with special colours, a colour tinter must be applied on the repaired area covering the intermediate coat before applying the pearl base. Pigments are very transparent. So, if the percentage of pearl pigments in the colour tinter is very high, the colour effect obtained will depend on the number of layers applied, the product load or the intermediate coat colour.

When painting with special colours, a colour tinter must be applied on the repaired area covering the intermediate coat paint before applying the pearl base.

The main special pigments that have a greater presence in the refinishing sector are ColorStream and Xirallic

ColorStream pigments are formed by silicon dioxide sheets coated with metal oxide. These allow the reflection of different colours and shades. They are geometrically even, and are developed by manufacturers to provide the bodywork with exclusive visual effects of changing shades and colours depending on the angle of vision and on the impact of light on the surface.

Xirallic pigments are composed of aluminium oxide sheets coated with metal oxides. The formulas containing these types of pigments are called “electric colours”. They provide a crystalline effect with high sparkle and gloss levels.

Tips for applying metallic colours

Failing to work and prepare the base paints or failing to observe the finish under Failing to work and prepare the intermediate coat paints or failing to observe the finish under optimal light source imitating sunlight are some of the reasons that will influence the correct application of metallic colours.

Let us look at some of the keys to follow to correctly apply complex metallic colours:

- Adapting the use of hardeners and thinners to room temperature and humidity

Adapting hardeners and thinners to the temperature will help the metal particles to be directed and coupled correctly.

This is especially relevant when the temperature is high. Here, we recommend using slower dilutions and hardeners to prevent the appearance of paint defects such as clouding or cloudiness. - Applying a final control coat

Applying a final effect coat or anchorage will help provide good colour-matching to the finish, and to correctly direct the metallic paint particles.

- Using the blending technique

In metallic colours, blending will allow for the part to better integrate with the other adjacent areas. It will improve colour-matching and minimise the appearance of possible painting defects.

- Correct application technique

A correct application technique makes it easier to match the metallic A correct application technique makes it easier to match the metallic colour, improving the paint’s coverage and the distribution of the particles (to avoid the flop effect).

To do this, it is advisable to direct the gun so that the spray hits the surface regularly, with overlapping coats, distributing the particles evenly. - Correct colour identification

It is important to identify the size of the metal or the shade of the pearl to assess the shade and make sure that it is the original colour. Once this is done, check the colour version that best matches.

- Correct application of the intermediate coat

Painting the filler plays a key role in colours with basecoat or three-coat finishes. Problems such as excessive product loading or using a filler colour that is not suitable for the finish colour can cause darkening of the metallic colour in some shades.

- Following the product’s technical data sheets

In short, as in many other cases, following the manufacturer’s technical data sheets (pressure, fan and material flow regulation) will be essential to ensure good metallic colour reproduction.

Conclusion

The correct application of metallic paint can sometimes become a real challenge for professional painters. Some colours like pearl white, metallic grey or pearl blue can generate doubts and problems during the repair process.

Knowing their composition and the most efficient application techniques and advice will help to get perfect finishes, free of defects, even in the more complex metallic colours.