When inspecting and evaluating damage to a vehicle, we must be sure to correctly identify the type of topcoat. This will give us the information we need to accurately assess the repair scope and complexity during the pre-repair phase.

Therefore, as professional painters, it is essential that we have an in-depth knowledge of the different car-painttopcoats.

How are topcoats classified?

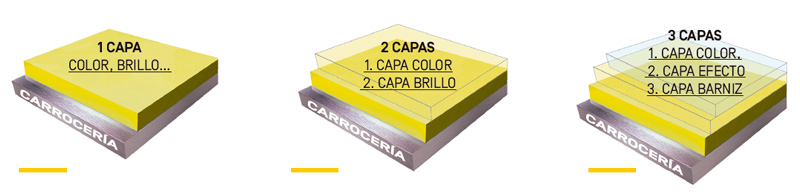

The paint used on a vehicle is classified by the number of topcoats (colour and clear coat). The use of one type of finish or another will be determined by factors such as the type of vehicle being repaired, the appearance we wish to achieve, or the application system used.

The most widely-used automotive paint systems are single-layer base coat and two-and three-coat topcoats. The painting process is adapted to the kind of paint used in the repair.

As bodywork and paint shopprofessionals, wemust know them in depth so we can optimise repair times and product and tool costs.

Pigment types in car paint

To better understand the coats that make up a vehicle’s paint coat, we must first know what each coat contains and what its properties are.

In general terms, car paint is composed of pigment, which is the component that gives it colour, and gloss, which is provided by the resin that is also part of the paint.

In most cases, pigments are differentiated by the type and number of special particles they contain:

Solid pigments

These pigments are composed of organic and inorganic particles that provide high opacity and coverage (one of the basic characteristics of paint). They enable us to obtain practically all plain primary and secondary shades and achromatic colours.

Special pigments

Also called “Flip Flop”, “Chameleon” or “Iridescent Chromatic”. They provide chrome effects, sidereal effects, even temperature-sensitive effects. They can produce alumina-effect (Xirallic) colour types.

Metallic pigments

Aluminium particles that givehigher opacity and a metallic appearance to the paint. Depending on their size (fine, medium and coarse) these particles will provide a varying degree of reflection and shapes (irregular or lenticular for more brilliant colours).

Pearl pigments

Manufactured from natural “MICA” particles coated with metal oxides (titanium), which, depending on the number of coats, produce different interference, absorption and reflection effects. This type of pigment is also known as pearlescent.

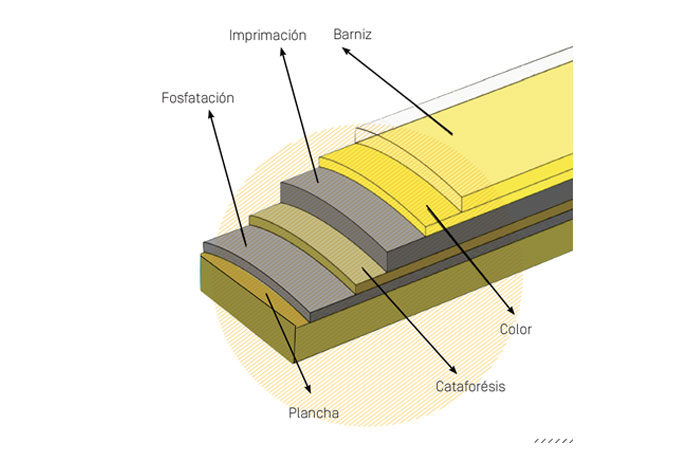

Paint coats on a new car

To be able to correctly differentiate the different finishing coats, we must understand about the substrates that go into the full coat of paint of a newlymanufactured car that has not been repainted.

The type and number of substrates will also vary depending on the type of material the paint is to be applied to (steel, aluminium or plastic). Generally, a coat of paint on sheet metal will consist of:

- Original horizontal coat thickness: 140 microns.

- Original vertical coat thickness: between 90 and 120 microns.

- Phosphating and passivating: provides anticorrosive protection and excellent adhesion.

- Cathodic electrophoresis: aqueous solution with + and – charged anticorrosive pigments. 20 microns.

- Filler: provides uniformity and adhesion to the topcoat. 40-50 microns.

- Finish:

- Single layer base coat: 40-50 microns

- Two-coat: 15 + 35-micron clear coat

- Three-coat: 15+15+ 35-micron clear coat

Types of paint used in car repainting

The process involving repairing and repainting a vehicle generally includes the types of paint used according to their position from the topcoat: base coat and topcoat.

Primer or insulating paints

This is the first coat of paint. It protects the metal and the provides a base for the finishing paint.

Applying this paint incorrectly will affect the finish, its colour matching, coverage or may even lead to defects.

Among this type of paint are products such as polyester putties, fillers, primers, adhesion promoters or elasticisers, among others.

Topcoat

As its name suggests, the topcoatis the paint on the surface.

Its purpose is to give colour, brightness and effect so as to reproduce the vehicle’s original appearance. It also protects against possible surface damage caused by chemical or mechanical agents.

Types of topcoats

As mentioned above, topcoats are classified by their number of coats:

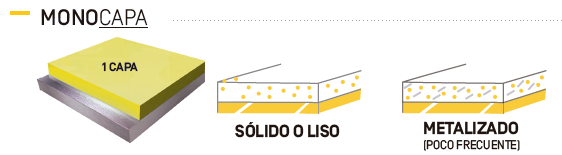

Single-coat topcoat

This is a single-coat topcoat. All the components required (colour, gloss level, chemical-mechanical and UV resistance) are blended in it.

This single coat gives the final appearance and protects the paint.

- Advantages: quickly applied. Very hard. Cost-effective.

- Disadvantages: lower chemical resistance and less variety of colours (metallic or pearl colours can be achieved, but in smaller quantities).

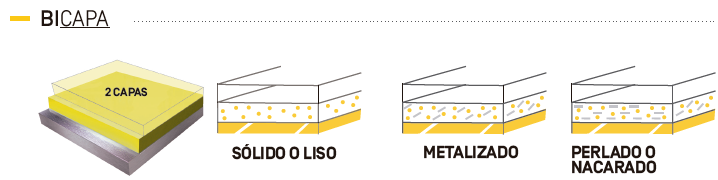

Two-coat topcoats

This is currently the most common topcoat. It consists of two coats, a first coat that provides the colour and effects, and a second coat that provides the sheen and the mechanical and chemical resistance required for its protection.

- Advantages: standardised, fast and cost-effective process. All colours available, including plain, pearlescent or special effects.

- Disadvantages: higher cost and more complex application than single layer base coat paint.

Types of two-coat topcoats according to pigments and resins:

- Two-coat solid effect paint: two-coat finishes without any effect (white, red, blue, etc.)

- Two-coat metallic effect paint: finishes with metallic pigments and generally small proportions of solid pigments that give the hue.

- Two-coat pearlescent-effect paint: this type of finish usually contains solid, metallic, pearlescent and even alumina pigments. It is the most widely used two-coat today.

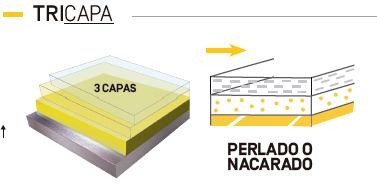

Three-coat topcoat

This topcoat consists of three layers.

- Coloured base.

- Special effect colour (transparent coat that allows light to pass through and reflects the intermediate coat).

- Clear coat (in some cases, the first clearcoat is dyed with a special pigment).

Below are the major advantages and disadvantages of the three-coat topcoat:

- Advantages: very bright colours, effects and reflections that cannot be achieved in any other way.

- Disadvantages: more expensive and more difficult to match than other topcoat systems.

Ways to differentiate between different types of topcoats

You can use several methods, depending on your level of experience and the accuracy of the information needed. From less to more reliable, these are:

Human eye

A professional painter with extensive experience will be able to tell at a glance whether the colour is solid, metallic or pearlescent, and the different types of finish.

The greatest difficulties can be encountered when distinguishing betweensingle-layer base coat and solid two-coat topcoats, or between pearlescent two- and three-coat topcoats. Of course, this method is the one that can be the most misleading.

Sanding

Another alternative would be to gently sand down an area of the surface you want to identify. If the sanding residue is whitish, you know that the last coat that was applied was clearcoat (two-coat). On the other hand, if the residue is of the colour of the vehicle, you would be looking at a single-coattopcoat.

However, this method is not as effective in differentiating a two-coat finish from a three-coat finish, as both have clear coat as their topcoat.

Colour formulation

In case of doubt, the fool-proof way to determine the pigments present and therefore the type of finish, would be by using the colour formulation.

SINNEK recommends using this method since, as well as correctly identifying the finish, you will obtain information about the mixture and its composition.

- If the formula contains only conventional basics in the mix, it will be a flat two-coat.

- If the formula contains metallics but not pearls, it will be a metallic two-coat.

- On the other hand, if the mixture contains some pearlescence, we will have a pearlescent two-coat.

In case of doubt, you can use SINNEK’s colour-management softwaretocheck this. You can also see our tutorial on how to use the spectrophotometer to measure colour.

Benefits on workshop profitability of understanding the types of topcoats

Correctly identifying a car’s topcoat when assessing itbefore repair is essential for performing the work in the most profitable way.

An expert eye, like that of a professional painter, can tell the difference between metallic and pearlescent particles with the naked eye because of the degrees brightness and hue they provide.

But there may be other profiles within the workshop, such as the manager or the supervisor, who do not have the identification skills that work experience provides.

Knowing what kind of topcoat a car has will help you determine:

The cost of materials and time to be spent on the work

Depending on the car’s topcoat, you will have to invest more or less time, which will affect the cost/hour ratio. Generally, a single-layer base coat paint repair will be less costly in time and product than a two- or three-coat repair.

Nowadays there are different ways of determining the precise kind of topcoat. This will minimise the chance of errors occurring during the repainting process and will give you more time and confidence when planning repairs. As mentioned above, using a spectrophotometer is currently the most reliable method.