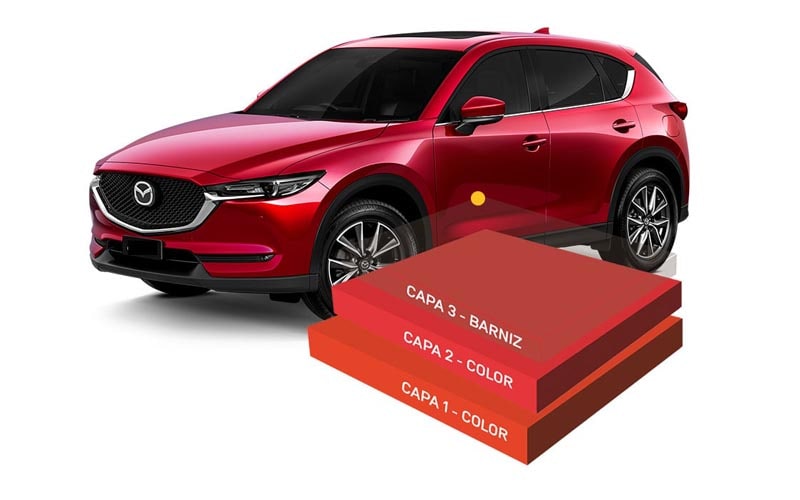

Mazda’s 46V Soul Red Crystal colour code is a three-coat reddish colour (candy effect) which, due to its composition and complexity, may give rise to matching difficulties for the bodywork and paint shopprofessional.

The SINNEK ACADEMY believes it interesting to create a specific content that helps professionalsto accurately reproduce this colour, through a simple and agile application process.

Differences between Mazda’s 46V and 41V colour codes

The 46V colour code is a more sophisticated evolution of Soul Red 41V, the Japanese manufacturer’s two reddish three-coat colours.

Both are very bright and shiny colours, but the 46V Soul Red Crystal colour is the brightest and hast the greatest aesthetic impact, because it has 20% more colour saturation and 50% more depth than its predecessor. In addition, it has a larger amount of smaller aluminium particles than the 41V colour code, which gives it a brighter surface.

Considered to be one of the most beautiful red body colours in history ,the 46V colour first saw the light of day with Mazda’s CX-5SUV, and was later used in other Mazda models.

Is it so complex to obtain an accurate reproduction of this colour in the body?

At present, it is undoubtedly one of the most challenging colours for a bodywork and paint shop.

Because of its greater complexity, professional painters must adapt the work and repair process to ensure optimal reproduction.

At SINNEK , we have developed a painting process that simplifies and speeds up the reproduction of complex three-coat colours such as 46V and other colours, such as Mazda’s 41V.A process aimed at reducing material costs and working time used, ensuring correct colour matching to prevent repeating the repair.

Steps to Correctly Reproduce 46V Soul Red Crystal

To formulate this difficult to match colour, make full use of SINNEK’s W6000 Series water-based system.

Unlike other processes on the market, for the correct reproduction of the Soul Red Crystal 46V colour you will not need to use dyed clear coat in the colour formulation.

Instead, use the basic WS/6314 Transparent Red, a product that is specially designed to repair complex colours with reddish shades, and which, being integrated within the water-based system, will allow to simplify and speed up the working time during the repair process.

This basic colour provides excellent colour matching, depth and brightness, while increasing the profitability of the repair, by reducing costs by more than half compared to other processes on the market. In addition, it is easier to blend.

To make it easier to reproduce and speed up this complex colour, follow the following steps:

- Choosing the right colour version

First, use the spectrophotometer to get an accurate colour reading.

Take a measurement in the area adjacent to the damage to be repaired in order to optimise integration of the part in the bodywork.

The colour of the different areas of the bodywork may vary slightly if the vehicle has previously been repainted.

Performing this measurement will help to choose the most accurate colour shade in the colour management software.

- Adjusting the filler colour to the finish colour

It is important to adjust the colour of the filler to avoid having to apply more coats than those required, to achieve a correct opacity and coverage.

Chose the filler colour shade indicated in the software. To reproduce the 46V Soul Red Crystal colour, use a light grey filler.

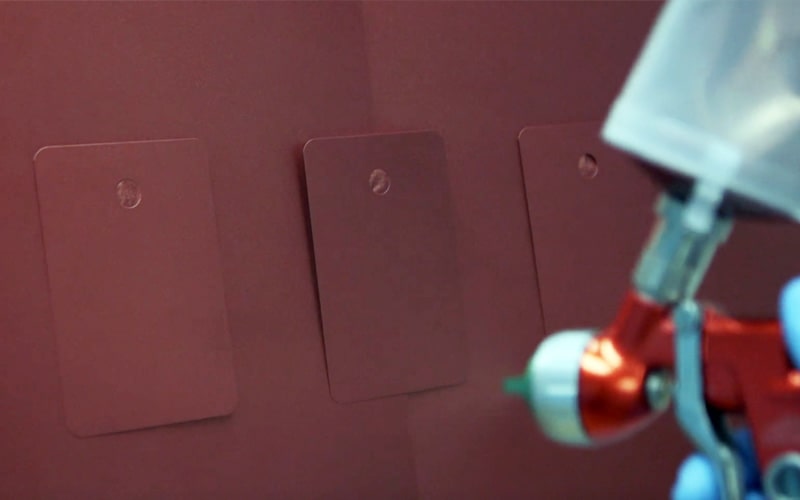

- Paint test cards to optimise colour matching

In order to optimise the colour matching of the part, make colour tests on 3 different paint test cards. This way, you will find out the ideal number of layers to apply for a correct colour reproduction.

Apply the first coat with full coverage of the paint test cards. Then, apply the different layers of the second coat on each paint test card (1 layer on the first, 2 on the second and 3 on the third). Finally, compare the tests on the surface adjacent to the damage to repair, and choose the test that shows the best match.

These tests must be carried out by the same painter who is going to repair the vehicle, as each professional will apply a different coat thickness or from a different distance, making different movements in each layer, and the number of layers required can vary from one professional to another.

- Applying the first coat – colour

Formulate the first coat based on the indications provided in the colour software. Adjust paint viscosity according to relative temperature and humidity. The dilution may range from 15 to 25%.

Add 5% activator to the mixture to harden and favour adhesion of the application. Adjust the gun according to the indications provided on the product data sheet.

Apply a first effect or anchoring coat, and then a second more even, extended and regular coat to the entire surface, without overloading the edges. – Finally, an effect coat, which will help to correctly direct the metallic particles of the colour.

- Applying the second coat of colour

Then, apply the second coat of colour. This coat will bring brightness and depth to the colour, allowing light to pass through and be reflected on the metallic particles.

Apply the number of coats established, based on the previously conducted test runs. Using a water-based system will prevent any clouding from appearing on the edges of the part, which are characteristic with this type of colour. In addition, evaporation times will be shorter, and a Venturi can be used to shorten this process.

In a complex colour such as 46V Soul Red Crystal, a recommended practice is to apply the product using the blending technique, in order to minimise any possible colour mismatch or colour leap, especially between parts and adjacent areas.

- Applying the third clear coat

Finally, apply the final coat with a high performance and easy to apply clear coat, such as SINNEK’s CC/1700. Apply two regular and even coats over the entire surface.

This will provide extra chemical and mechanical resistance to the finish and prevent the clear coat from copying the structure of the base, which could lead to possible painting defects.

- Result

Following the steps described will lead to an excellent colour match of the finish, and full customer satisfaction.

Conclusion

As we have seen, the greater complexity of this colour lies above all in the correct adaptation of the products and time available for the repair.

This adaptation is intrinsically more complex but paying special attention to the critical steps of the process from the start, and following the manufacturer’s indications and recommendations, will enable you to master the application of Soul Red Crystal 46V and other three-coat colours of similar complexity.