The arrival of summer and the heat that goes with it has a direct influence on the repair and painting work that is carried out on vehicles atbodywork and paint shops. This is mainly due to the rheological properties of the materials that are used.

High temperatures make paint dry faster or make the parts to be repaired and the air expelled by the gun warmer. This forces the professional painter to adapt the paint preparation, application and drying processes.

Relative humidity and environmental temperature or the temperature of the part (plastic, metal sheet) and product are factors that must always be keep in mind during repairs, but it is in extreme heat conditions, when it becomes even more important for achieving a quality finish.

Following a series of guidelines and practical advice will lead to obtaining excellent final results when painting a car in summer or at any other time of the year, regardless of the weather conditions.

1. Correct choice of thinner and hardener depending on the room temperature

Adjusting the mixture to obtain a correct viscosity for the application will be essential with high temperatures. Make sure that the paint does not dry out too quickly.

In addition, the size of the surface to repair will influence the choice of the thinner and hardener to use. The larger the surface, the longer the drying time required.

Therefore, you should adapt the amount of thinner you use, reducing the dilution of the mixture when the temperature is high.

You should work with the mixing ratioranges indicated in the product’s technical data sheet, an use a compatible thinner adapted to the paint system used (same manufacturer) in order to optimise the final result and prevent any possible defects from appearing in the paint layer.

As for the choice of hardener, use a slow hardener that allows delaying the paint’s drying, ensuring a correct gloss and appearance of the finish paint. This feature will also help to better orient the effect particles of metallic or pearl colours during application.

SINNEK has a wide range of hardeners, which in combination with their different compatible products, allow adapting the application process to all types of contexts and situations.

Regardless of the size of the surface to paint, if room temperature is around 20ºC-30ºC, use medium hardeners such as HA/8020 or HA/8055.

If room temperature is above 30°C, use slow hardeners: HA/8010 or HA/8045. Check the technical data sheets and the indications on the packaging for product compatibility.

2. Relative Humidity

Depending on the region you are in, relative room humidity will impact noticeably on the application process of the water-based two-coal paint.

Obviously, in dry environments, water-based paint will dry faster than in regions with higher humidity levels.

This can lead to a greater difficulty in the integration of the coats applied. A correct adjustment of the mixture and product will keep the layer humid long enough to achieve a correct uniformity and extensibility.

3. Adapting the schedule to the work processes

In geographical areas, where high temperatures are frequent, it may be advisable to plan the work in advance, changing the production process schedules during the warmest periods.

This way, you will take advantage of the early morning and late afternoon hours, when the temperature is lower, to apply the paint in the booth.

During the central hours of the day, you will carry out preparatory work, applying putty, filler or masking work pending.

4. Adapting the application process and products

In extreme heat conditions, adapt the repair process and the products used in the most comfortable and safe way to ensure a good finish paint.Nowadays, polyester putties are usually fast reacting or drying.

However, you can slightly vary their drying speed depending on the amount of hardener (benzoyl peroxide) used in the mixture.

This will give professionals enough time to apply the putty on the surface to repair, without having to waste product during the application.

With regard to the filler, you must take into account the type of hardener used and the time elapsed between the preparation of the mixture and its subsequent application, since with high temperatures, the time required for the filler to harden can be substantially lower, and this will make its application and behaviour more difficult.

During the application of the finish paint, it is crucial that you follow the indications provided in the product’s technical data sheet for high temperatures. Make a wet and uniform application, without overloaded coats of product and always respecting the established drying times.

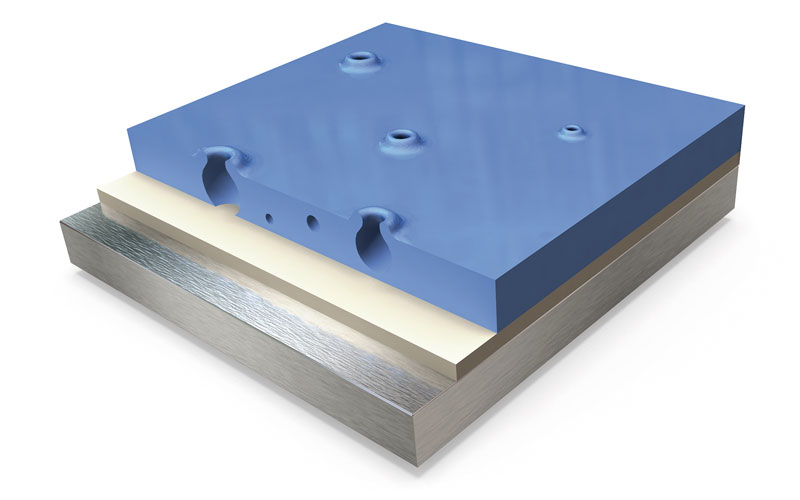

5. Storage and handling temperature

Since body paint is a chemical product, its properties can vary as a result of high room temperatures.

The products’ ideal application temperature should be around 20ºC-25ºCto guarantee a correct chemical reaction between the paint and its hardener. Similarly, the ideal storage temperature will range from 15ºC to 30ºC.

6. Most common defects due to high temperatures

High temperatures increase the requirements and complexity of a repair. Different painting defects will appear if you do not follow the previously described advice. The most common problems include the following:

Loss of gloss

With high temperatures, an incorrect use of hardeners and thinners, and failing to observe the drying times or applying an excessive load of product, can result in a loss of gloss of the final coat.

Boils

The use of a hardener or thinner that acts too quickly, preventing the solvent from evaporating completely from the lower coat, will favour the appearance of boils. In addition, a sudden change in temperature, known as “thermal shock”, can lead to the appearance of a final coat of moisture.

Clouding

High temperatures hinder the orientation of effect particles, preventing them from being sufficiently moist when in contact with the part. This incorrect orientation of the particles can cause changes in the shade of colour, or the appearance of clouding or cloudiness in the finish.

Conclusion

Taking this series of tips into account when applying the paint in extreme heat conditions will provide you with added safety and will minimise any possible errors during the repainting process. In addition, in places where temperatures are high for most of the year, taking the necessary measures to keep the profitability and productivity rates required for sheet metal and paint repairs will be essential.