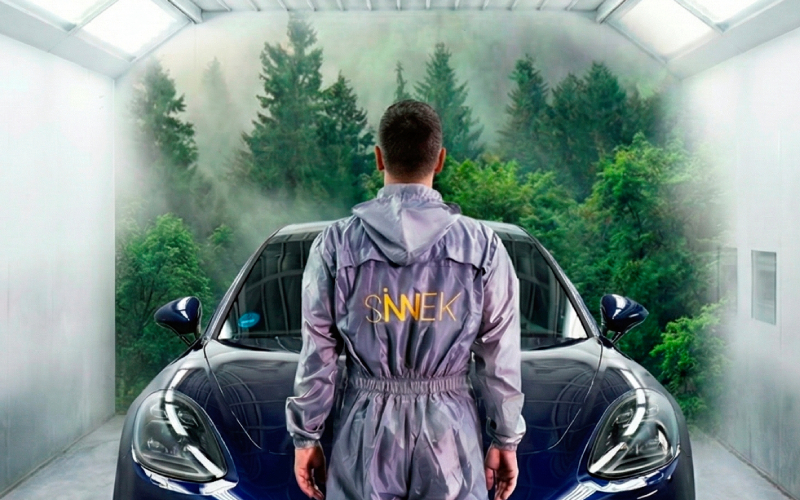

Bodyshop efficiency is no longer measured solely by speed or productivity. We are moving towards a more conscious and responsible evolution in the way we work, and this is where sustainability has become a strategic factor.

A new scenario in the bodyshop sector where work processes must combine innovation, performance and environmental awareness.

For this reason, at SINNEK we have designed the LOW IMPACT SYSTEM high-efficiency process, whose main objective is to create a more respectful, efficient and safe working environment for the bodyshop.

What does the LOW IMPACT process consist of?

LOW-IMPACT SYSTEM is a process that seeks to minimise the environmental footprint of the refinishing process without compromising performance or the final quality of the finish.

It is not just a set of products. It is a working methodology that integrates:

- Lower VOC emissions.

- Reduced solvent exposure for the professional.

- Less waste.

- And a reduction in booth energy consumption.

A high-efficiency process that aims to produce less impact, maintaining the same standards of excellence demanded by today’s market.

LOW IMPACT SYSTEM seeks to minimise the environmental footprint of the refinishing process without compromising performance or the final quality of the finish

Advantages of use in the bodyshop

From environmental impact to operator health and process efficiency, every phase of the LOW-IMPACT SYSTEM process has been formulated with a clear vision: to improve the overall performance of the repair without compromising environmental responsibility.

Minimising environmental impact: painting with a conscience

Thanks to the integration of products with low Volatile Organic Compound (VOC) content, and the use of water-based technologies, the following is achieved:

- A significant reduction in pollutant emissions into the atmosphere, especially in booths without advanced air treatment systems.

- A lower ecological footprint for each repair, actively contributing to compliance with stricter environmental regulations and the bodyshop’s sustainability goals.

In other words, every application of the system represents a real commitment to the environment.

Professional safety and well-being

LOW-IMPACT SYSTEM provides a positive impact on operator health. How does it achieve this?

- By decreasing exposure to solvents and volatile particles, which are harmful in repeated or prolonged exposure.

- By creating a cleaner and safer working environment in the long term.

This not only improves the professional’s well-being but also promotes greater efficiency, concentration and job satisfaction. In times where attracting and retaining technical talent is a challenge, working in healthier conditions is a differential advantage.

Sustainable operational efficiency: fewer resources, more performance

LOW-IMPACT SYSTEM is not only aimed at optimising the sustainability of each repair but also at improving the profitability indicators of the bodyshop itself:

- Reduces waste generation: by using optimised systems with a lower amount of solvents, the volume of surplus materials and hazardous waste is minimised.

- Decreases energy consumption: thanks to the use of air-drying products and low flash-off times, the intensive use of heat in the booth is minimised.

All of this translates into a tangible improvement in the cost per process, aligning sustainability with profitability.

How the LOW IMPACT process is structured: the products that comprise it

LOW IMPACT SYSTEM is a structured technical process, where every product, every drying time and every application is designed to minimise environmental impact without sacrificing finish excellence.

Foundation preparation: UHS Primer PF/

Foundation preparation is the basis for subsequent performance. SINNEK’s UHS primer PF/ stands out for its:

- High filling power, which reduces the need for additional applications.

- Excellent ease of sanding, optimising labour times.

- Availability in three shades for correct colour adaptation:

- PF/9110 White

- PF/7040 Medium Grey

- PF/7016 Dark Grey

- Drying cycles adjusted for real energy efficiency:

- At 60 °C → 20 minutes

- At 20 °C → 30 minutes, reducing energy consumption

- With infrared (IR) → just 10 minutes

This high-efficiency primer paint allows for a perfect balance between technical performance and the optimisation of booth consumption.

Colour base application

At the core of the process is the W6000 SERIES painting system, a water-based technology basecoat that combines efficiency and sustainability.

Its main advantages:

- A paint system with colourimetry, performance and hiding power superior to other systems on the market.

- Exact colour reproducibility, without repetitions. Security and guarantee in your work processes.

- High evaporation speed (15-20 minutes), which implies lower booth usage and energy expenditure.

For painting interiors, non-visible areas of the bodyshop or replacement parts, LOW IMPACT incorporates WA/6075 UNDERHOOD resin. It stands out for:

- Single-step application, optimising work time.

- Reproduces the original OEM finish, without sacrificing quality.

- Considerably reduces material consumption.

A perfect ally for parts where the balance between work time, product consumption and result are key factors.

Final coat: CC/1700 HIGH PERFORMANCE Clearcoat

For the lacquering process, LOW IMPACT integrates UHS 2:1 CC/1700 HIGH PERFORMANCE clearcoat, formulated with latest-generation resins that ensure smooth application and high extensibility.

- Low VOC content composition.

- Excellent chemical and physical resistance, even in adverse conditions.

- Drying at room temperature (20 °C), which allows drying processes without turning on the booth, eliminating associated energy costs.

In short, a clearcoat that allows for a professional finish while minimising the environmental footprint, ideal for bodyshops seeking profitability aligned with their values.

Conclusion: an opportunity to move towards a more conscious, responsible and profitable bodyshop

Overall, SINNEK’s LOW-IMPACT SYSTEM offers a clear path to evolve towards a more sustainable work model, without giving up the quality or performance expected by the end customer.

A complete, measurable and replicable process that turns every repair into an opportunity to move towards a more conscious and profitable bodyshop.

High-efficiency SINNEK processes

At SINNEK, we have other high-efficiency processes specially designed for different objectives:

- SPEEDFLOW SYSTEM: Transform time gain into real profit.

- LOW IMPACT SYSTEM: A responsible, conscious and profitable way of working.

- ENERGY SAVING SYSTEM: Perfect balance between energy saving and finish quality.

- ULTRA GLOSS SYSTEM: Repairs with differential quality.