Aquí tienes la traducción completa del último post al inglés británico, manteniendo todo el código HTML y los bloques de WordPress, y utilizando el término bodyshop como solicitaste:

“””

In the refinish sector, there are repairs that transcend the technical and become an aesthetic statement. Where every reflection matters and prioritising the enhancement of repair quality to the maximum is key.

In order to offer the professional a differential quality in every repair, at SINNEK we have developed ULTRA GLOSS SYSTEM, the high-efficiency process designed for the most demanding finishes and clients.

A solution that raises the concept of premium finish to a new level in search of maximum gloss, chromatic fidelity and colour depth.

What does the ULTRA GLOSS SYSTEM process consist of?

ULTRA GLOSS SYSTEM is not a conventional work process. Developed with the aim of obtaining the highest quality, it integrates high-end products and an application workflow designed to:

- Enhance colour matching even in the most complex shades

- Generate a depth and mirror-shine finish

- Guarantee extreme durability and protection against external aggressions

Because in certain repairs, excellence is not optional: it is mandatory.

ULTRA GLOSS SYSTEM is the natural choice for premium finishes, high-level restorations or exclusive customisations

Advantages of use in the bodyshop

ULTRA GLOSS SYSTEM is designed to excel in four key areas:

1. Maximum colour fidelity

Thanks to the W6000 SERIES water-based basecoat system, the process guarantees precise matching even in highly complex three-stage, pearlescent or metallic colours.

Ideal for partial or full repairs where visual colour continuity is essential.

2. Differential aesthetic finish

The system has been designed to provide a “mirror effect” finish to the surface, with a deep, sharp and immersive gloss.

This effect not only raises the visual appeal of the repair but also increases the perceived value of the work carried out.

3. High durability and resistance

ULTRA GLOSS SYSTEM does not sacrifice protection for aesthetics.

The final clearcoat layer offers exceptional resistance to scratching, chemical agents, UV and extreme weather conditions.

4. Guaranteed satisfaction for the most demanding clients

Designed for demanding restorations, exclusive customisations or premium repairs.

A natural choice for bodyshops that want to position themselves in a high value-added segment.

How the ULTRA GLOSS SYSTEM process is structured: the products that comprise it

Below we detail the key components of the system and in which phase or type of repair each one is integrated:

1. Foundation preparation

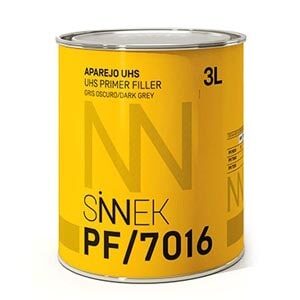

Every exceptional result is built from the foundation, and that is where SINNEK’s UHS Primer PF/ makes the difference.

A perfectly smooth, uniform surface with high surface tension, which allows for optimal colour integration and great reflection from the final clearcoat.

- High filling power, which reduces the need for additional applications.

- Excellent ease of sanding, optimising labour times.

- Availability in three shades for correct colour adaptation:

- PF/9110 White

- PF/7040 Medium Grey

- PF/7016 Dark Grey

- Drying cycles adjusted for real energy efficiency:

- At 60 °C → 20 minutes

- At 20 °C → 30 minutes, reducing energy consumption

- With infrared (IR) → just 10 minutes

2. High colour precision

In a process where visual quality is everything, the colour application cannot be just another step. It must be the soul of the finish, the moment when the bodyshop work gains character and personality.

For this reason, SINNEK’s W6000 SERIES water-based basecoat system becomes the key to the ULTRA GLOSS SYSTEM process. Its main technical virtues make it a benchmark in the premium segment:

- A paint system with colourimetry, performance and hiding power superior to other systems on the market.

- Exact colour reproducibility, without repetitions. Security and guarantee in your work processes.

- High evaporation speed (15-20 minutes), which implies lower booth usage and energy expenditure.

3. Lacquering with maximum productivity

Every great refinishing process deserves a closure to match. In the ULTRA GLOSS SYSTEM, that closure is provided by the UHS CC/1758 clearcoat: a formulation developed to offer an impeccable, durable and visually striking finish.

This clearcoat is not just a protective layer. It is the element that defines the final perception of the work, transforming it into a piece of high aesthetic value.

Its attributes make it the ideal ally for demanding restorations, exclusive customisations or any repair where visual quality is key:

- Deep and perfectly uniform gloss, which enhances colour depth and multiplies the mirror effect.

- High extensibility, allowing for a smooth and continuous application on complex surfaces, without accumulation areas or unwanted textures.

- Outstanding resistance to chemical agents, scratching, weathering and UV degradation, ensuring the finish remains impeccable over time.

Compatible with SINNEK’s HA/8010, HA/8020 and HA/8030 hardeners, it allows working without the need for ultra-fast additives, preserving aesthetic quality and control over application time.

Conclusion: excellence in refinishing

ULTRA GLOSS SYSTEM has been developed for professionals seeking to differentiate themselves through finish quality.

A technical system that combines precision, aesthetic performance and maximum durability, designed to meet the most demanding standards in high-value restorations, customisations or repairs.

High-efficiency SINNEK processes

At SINNEK, we have other high-efficiency processes specially designed for different objectives:

- ENERGY SAVING SYSTEM: Turns every repair into a smart savings opportunity.

- ULTRA GLOSS SYSTEM: Takes the concept of premium finish to a new level.

- SPEEDFLOW SYSTEM: High productivity to minimise the vehicle’s stay in the bodyshop.

- LOW IMPACT SYSTEM: A perfect balance between maximum quality and the highest sustainability.