In a context where energy costs continue to rise, the bodyshop has the choice to accept it as an inevitable cost… or transform it into a strategic opportunity to improve its profitability.

With the aim of providing a tool that meets this need, at SINNEK we have developed ENERGY SAVING SYSTEM, a technical process that significantly reduces booth energy consumption, without altering the finish quality or compromising delivery times.

Because today, energy efficiency is not an option. It is a competitive advantage.

What does the ENERGY SAVING process consist of?

ENERGY SAVING SYSTEM is a working methodology based on fast-drying and high-efficiency products, designed to minimise dependence on external heat sources (such as booths or IR lamps) without giving up:

- Speed in repair cycles

- Finish quality

- Process safety

It is, in short, a way to work in a more profitable, productive and sustainable way in a context where energy optimisation in the bodyshop is indispensable.

ENERGY SAVING is the shortest path to a more profitable, productive and energy-sustainable bodyshop

Advantages of use in the bodyshop

The ENERGY SAVING SYSTEM is built around three very specific operational advantages:

1. Less dependence on heat sources

- The products that comprise this system are formulated to offer great performance in air-drying or short thermal cycles.

- This allows for the reduction or elimination of the use of heat sources such as booths or infrared lamps, with the consequent energy savings.

2. Real energy savings in the booth

- From foundation preparation to the final lacquering, every stage of the process has been optimised to reduce booth energy consumption.

- This translates into a direct reduction in the operational cost per repair, without affecting the work pace or the bodyshop’s quality standards.

Sometimes lower energy consumption does not mean lower performance. It means more efficiency.

3. Greater operational sustainability

- Lower energy consumption → lower carbon footprint

- Faster processes → higher productivity

- SINNEK technology → guarantee of premium quality

How the ENERGY SAVING process is structured: products that comprise it

Below we detail the key components of the system and in which phase or type of repair each one is integrated:

1. Ultra-fast foundation preparation

For foundation preparation, ENERGY SAVING SYSTEM integrates ultra-fast drying primers, which do not require sanding.

The result? A reduction of up to 40 minutes in the foundation preparation process.

The use of this type of primer minimises waiting times. Its application allows you to move directly to the next step without interruptions or unnecessary waits.

1.1 Small repairs

For small repairs or spot repair, the ENERGY SAVING SYSTEM process integrates the SPF/UV ultraviolet spray primer.

Its drying in just 30-60 seconds with a UV-A 100 MW/CM2 lamp raises the productivity of the repair to a new level while reducing booth usage.

With just 1 or 2 coats of application, and flash-off of around 20 seconds between layers, we will have a perfectly homogeneous surface ready for the application of the colour base.

2.1 Painting of new or replacement parts

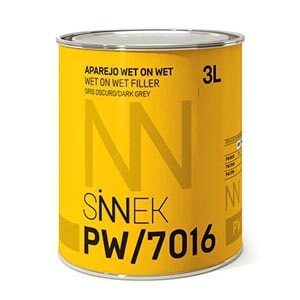

For this type of repair, ENERGY SAVING SYSTEM uses the PW/ wet-on-wet primer.

This primer, available in 3 different shades (PW/9110 – WHITE, PW/7040 – GREY, PW/7016 – DARK GREY), provides excellent coverage without the need for sanding.

With a smooth and satin appearance, it provides a surface that is dry and ready for painting in just 20-30 minutes after application.

2. Colour application

This process uses the W6000 SERIES water-based basecoat system, which, in combination with the SO/5100 ACCELERATOR ADDITIVE, allows the flash-off time of the colour base to be reduced by around 20-30%, optimising its performance even in high humidity and/or low temperature conditions.

Less evaporation = less heat usage = lower energy expenditure

This combination of products facilitates lower energy consumption and greater productivity for each repair.

As a result, we will have a regular, homogeneous surface, with high coverage and excellent integration between parts that will minimise the need for rework to the maximum.

3. Lacquering with maximum productivity

Depending on the type of repair and the objectives set for it, SINNEK’s ENERGY SAVING SYSTEM considers two differentiated paths:

3.1 Maximum hardening speed

If the main objective is to speed up the hardening and drying speed for ultra-fast delivery, we will use the CC/1800 Ceramic Plus clearcoat.

This high-performance clearcoat, in combination with the HA/8070 ultra-fast hardener and the PUR AC/1650 accelerator additive, allows the surface to dry in just 5-10 minutes at 60ºC.

The CC/1800 Ceramic Plus clearcoat increases repair efficiency, thanks to the possibility of handling the vehicle just one hour after application.

3.2 Ultra-fast drying

On the other hand, if we are looking for ultra-fast drying to make deliveries in record time, the best solution will be the CC/1770 UHS Express clearcoat.

A product that guarantees great gloss and depth, without sacrificing durability and surface resistance.

Both clearcoats are compatible with the new SO/8520 fade-out additive, which facilitates perfect finishes on small repairs.

Conclusion: energy intelligence, positive impact

ENERGY SAVING SYSTEM proves that it is possible to maintain high quality standards while controlling the bodyshop’s energy consumption.

It is a system that optimises every step of the refinishing process to reduce costs, save time and contribute to a more sustainable work model.

High-efficiency SINNEK processes

At SINNEK, we have other high-efficiency processes specially designed for different objectives:

- ENERGY SAVING SYSTEM: Smart energy savings.

- ULTRA GLOSS SYSTEM: A responsible, conscious and profitable way of working.

- SPEEDFLOW SYSTEM: Transform time gain into real profit.

- LOW IMPACT SYSTEM: A responsible, conscious and profitable way of working.