HIGH PRODUCTIVITY TO MINIMIZE VEHICLE TIME IN THE BODYSHOP

HIGH PRODUCTIVITY TO MINIMIZE VEHICLE TIME IN THE BODYSHOP

THE SPEEDFLOW SYSTEM PROCESSIS SPECIALLY DESIGNED TO INCREASE WORKFLOW AND PROFITABILITY PER REPAIR CYCLE.

WHAT IS THE SPEEDFLOW SYSTEM?

SPEEDFLOW SYSTEM is a high-efficiency process composed of state-of-the-art products, with a clear main objective: To minimize the vehicle’s time in the body shop and maximize the profit of each repair.

KEY BENEFITS

1. DRASTIC REDUCTION IN CYCLE TIME

Reduces the vehicle’s time in the spray booth, increasing body shop turnover.

2. OPTIMIZATION OF OPPORTUNITY COST

Optimizes the workflow opportunity cost and maximizes the use of tools, preparation zones, and the booth.

3. ENERGY SAVINGS

Composed of products with ultra-fast drying cycles: the perfect ally to reduce energy consumption.

4. INCREASED PRODUCTIVITY

More cars ready in less time without compromising finish quality.

PRODUCTS INCLUDED

1. PRIMER FILLERS  30"-20'

30"-20'

Ultra-fast primers requiring no sanding, reducing undercoat preparation time by up to 40 minutes.

1.1 Fast repairs

SPF/UV UV PRIMER FILLER

30-60″

30-60″ 1-2 coats

1-2 coats 20″

20″

1.2 New or replacement parts

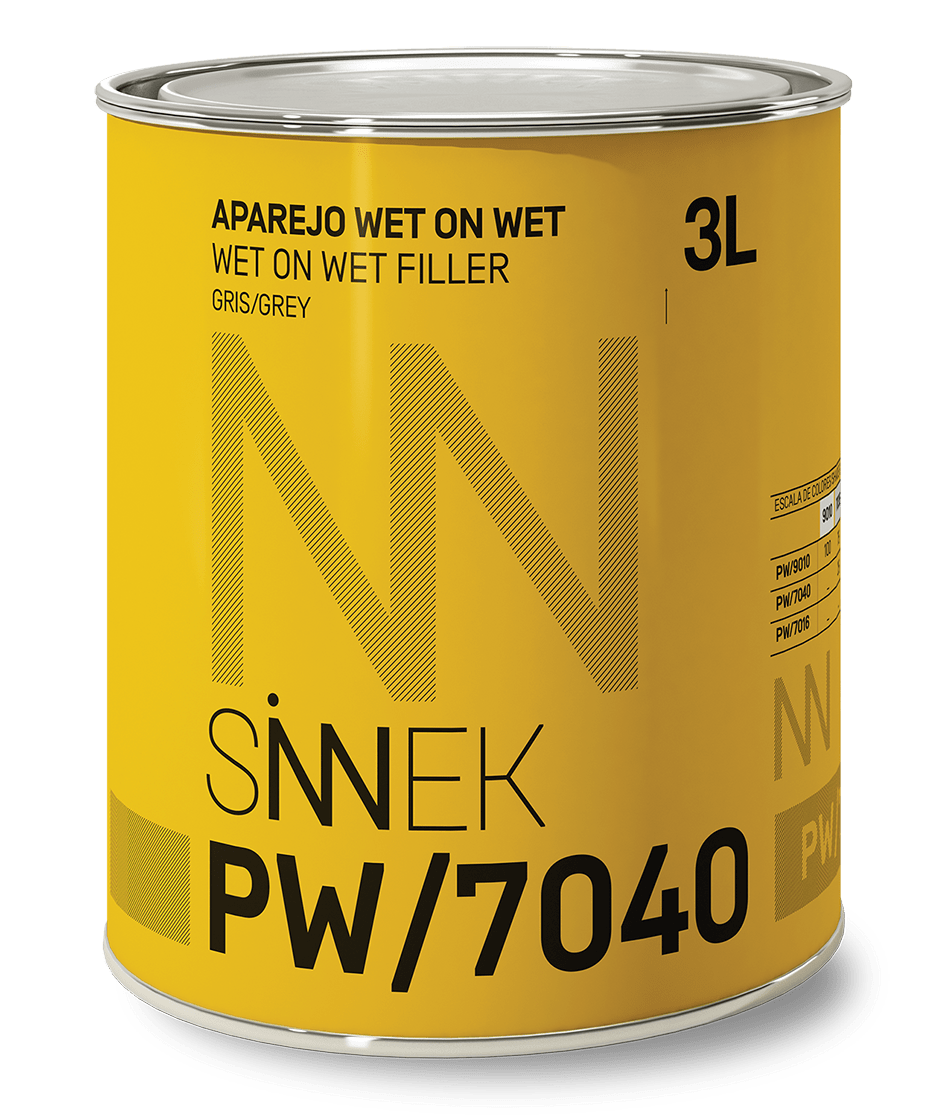

WET ON WET FILLER

20-30′

20-30′ No sanding required

No sanding required

2. COLOR  10-15'

10-15'

The SERIE W6000 Basecoat System + SO/5100 ACCELERATOR ADDITIVE to reduce the flash-off time of the color base.SERIE W6000 BASECOAT SYSTEM+ WA/6080 FAST DRY ADDITIVE+ ACCELERATOR ADDITIVE SO/5100

10-15′

10-15′

3. CLEAR COAT  5-10'

5-10'

The SPEEDFLOW SYSTEM process integrates different clear coat options depending on the final application objective.3.1 To speed up curing/hardening

CC/1800 CERAMIC PLUS CLEARCOAT

+ AC/1650 PUR ACCELERATOR ADDITIVE+ HA/8070

20ºC: 1h / 20-30′ (AC/1650)

20ºC: 1h / 20-30′ (AC/1650) IR: 20′ / 10-15′ (AC/1650)

IR: 20′ / 10-15′ (AC/1650) 60ºC: 10′ / 5-10′ (AC/1650)

60ºC: 10′ / 5-10′ (AC/1650)

3.2 To maximize drying speed

CC/1770 UHS EXPRESS CLEARCOAT

+ HA/8070

20ºC: 40′

20ºC: 40′ IR: 5′

IR: 5′ 60ºC: 10′

60ºC: 10′