In a previous post, we talked about the different types of car paint finish. We explained the characteristics and composition of each one, and the importance of correctly identifying them for the bodyshop’s profitability.

The purpose of this article is to deepen the knowledge of the three-coat paint finishes. The demand for this paint system increased among drivers due to its aesthetic appeal and spectacular nature.

What are Three-coat colours?

Initially, three-coat colours were reserved only for premium and high-end cars because of their high cost.

However, over time, its use spread among manufacturers. At present, most leading brands have this type of colour in their catalogue for their newer models.

Despite having a higher cost compared to other finishes, the demand for the three-coat colours among drivers is becoming increasingly significant.

The spectacular finish and the colour’s vividness are some of the reasons why three-coat paint is becoming more and more popular.

On the other side of the scale is the professional painter, for whom the complexity of the repair and the demand for optimal results in repainting increases.

This technological evolution of colour also entails a greater complexity and preparation, which will certainly have an impact on the time and cost of the repair.

It is therefore essential that professionals have the appropriate knowledge to tackle this type of work.

The step of applying solid colours to metallic colours was already a major leap in the day-to-day running of a bodyshop.

The emergence of these new colours with metallic and pearl effect pigments (Colorstream, etc. Xirallic) have multiplied the work options and their difficulty. If we add to this the fact that each manufacturer can have a unique type of application for one colour formula, or use different colour tinters to obtain the same result, the possibilities increase exponentially.

Coats that make up three-coat car paint

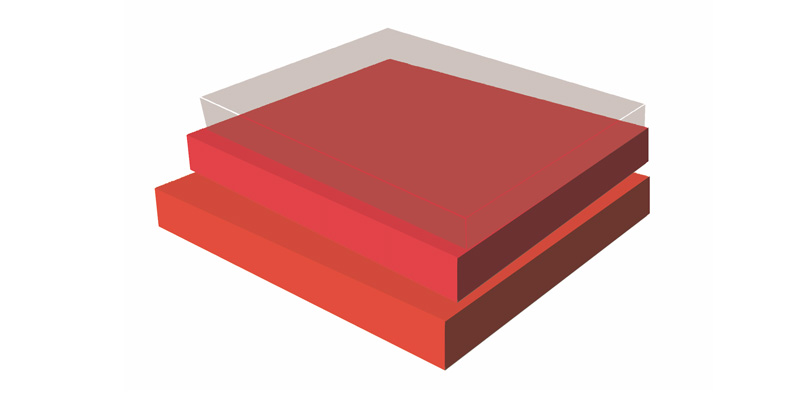

The three-coat finish is a type of car paint finish that consists of the following coats:

- First coat: an intermediate coat, composed of different tinters of the painting system. This will provide the generic shade to the finish.

- Second coat: this coat’s composition may differ from one manufacturer to another. Some painting systems use a translucent colouring coat, which allows light to pass through and be reflected on the intermediate coat. For greater simplification and swiftness in processes, SINNEK has developed an innovative application system that optimises colour matching in complex three-coat colours, based on a special tinter that is integrated within the W6000 series system, WS/6134 Transparent Red. This tinter provides many advantages over the traditional dyed clearcoat system, such as reduced costs and repair time or improved blending capacity.

- Third coat: a final clearcoat that aims to provide the gloss and protection required in the finish.

The main difference between basecoat and three-coat colours is that the latter provide greater colour vividness, a mixture of depth effects and a variety of reflections.

Types of three-coat finishes

Depending on the type of pigmentation in both the first and second coats, three-coat finishes can be classified as:

Three-coat finish with solid colour / pearl effect

This three-coat finish is usually used in red and yellow pearl colours, but especially in pearly whites.

It is undoubtedly the most widely used type of three-coat among manufacturers and consumers, and has become a trend, due to its colourfulness when exposed to a source of bright light such as sunlight. This is achieved by applying the following coats:

- A first coat of the solid colour tinter, within the grey scale, that will not have an impact on the final colour, but serves to get the mixture.

- A second coat with a semi-transparent pearl effect, that gives depth to the solid intermediate coat colour and reflections depending on the impact of light.

Three-coat finish with metallic or pearl base / solid effect

This option is becoming increasingly popular, and it is becoming more and more frequent to see cars with this type of three-coat finish on the roads. This is achieved by applying the following coats:

- A first metallic base coat (usually silver), within the grey scale, that has no impact on the final colour, but serves to achieve the mixture.

- A second coat of semi-transparent tinted clearcoat, that acts as an effect coat. This coat is composed of resin, along with tinters or additives that provide colour. Although it is called a clearcoat or dyed lacquer, it actually works as a second colour tinter, which is unhardened and is applied before the lacquer. This coat will dye the metallic base coat, giving it a very striking metallic shine.

The best known three-coat finishes on the market include pearl reds like Ford’s Hot Magenta (9RTEWTA), green like the Ultimate Green (9GFE5ZA) and three-coat red like Peugeot’s or Citroën’s Rouge Babylone (LKR), Renault’s Rouge Flamme (NNP), Alfa Romeo’s Rosso Competizione (134/B) or Mazda’s popular Soul Crystal Red (46V).

How to repaint using a three-coat colour

SINNEK always focuses on following the technical data sheet specifications in terms of drying times, gun adjustment or application of the effect coat, to minimise the occurrence of possible errors in repairs.

Due to its greater complexity, three-coat finish is a type of finish that involves more working time and cost of materials (effect coat materials, mixing container, etc.) than single stage or basecoat colours.

The repair process involves the following steps:

1. Choosing the right colour version

To select the correct colour code, you must first know if the vehicle has been repainted or if on the contrary it keeps its original factory colour. If it has undergone any previous bodywork repairs, we recommend using the spectrophotometer for a correct colour reading.

This way, possible errors in colour matching will be minimised, and a much more accurate colour information will be obtained than if you took the colour card corresponding to the model’s manufacturing colour code as reference.

2. Cleaning and degreasing of the surface

Thoroughly clean the surface to be repaired with degreasing agent and a dusting cloth.

3. Determining the number of effect coats to be applied on the base coat.

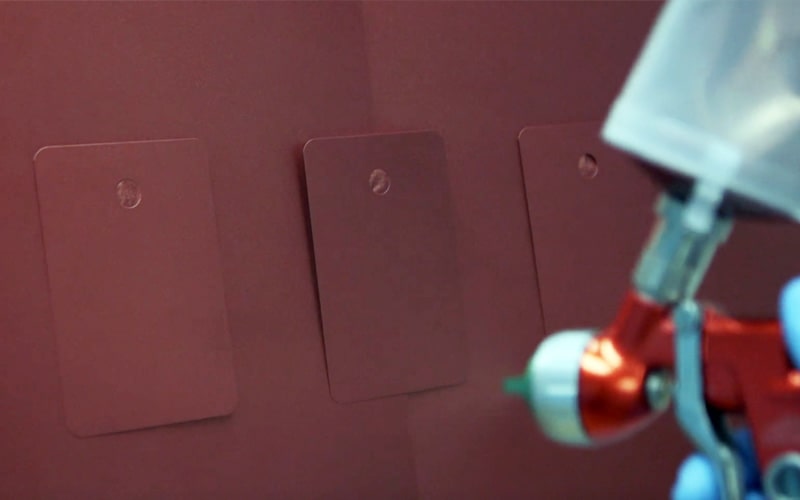

Conduct different colour tests on different paint test cards.

This will allow adjusting the final colour and knowing how many layers of the second base you should apply to get the best result. The test will consist in:

- Applying the first basecoat (intermediate coat) + established flash-off time. This coat is always activated in the SINNEK W6000 Series to ensure the stability and reaction of the process. You have 1 hour (depending on the room temperature) from the time you mix it with the activator.

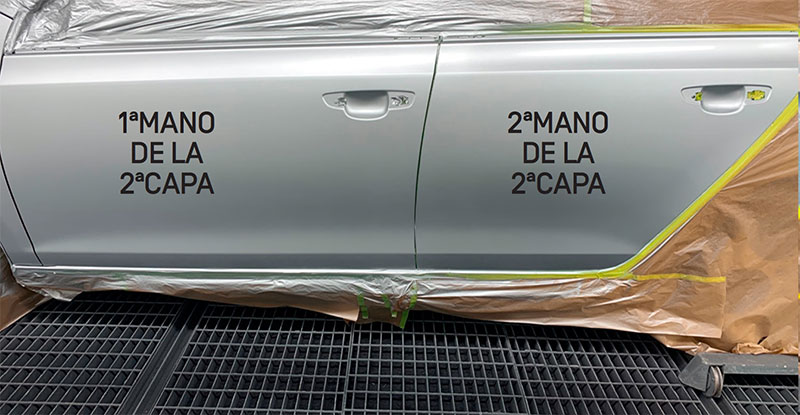

- Apply a second basecoat (number of layers depending on the colour) + established flash-off time.

- Apply the clearcoat + established flash-off time.

Once all the paint test cards are ready, compare them with the surface of the part to be repaired, to find out which one reproduces the colour most accurately, and how many layers is most suitable.

Each professional can apply the coats from a different distance or making different movements, so the number of effect coats required may vary from one painter to another.

It should also be noted that the coat thickness of a three-coat finish will be much greater than that of other finishes.

If too thick, it may cause the waterborne basecoat paint to contain some humidity. This will hinder its hardening, and subsequently affect the resistance of the top clear coat.

To prevent this problem, following the manufacturer’s recommendations on flash-off intervals between layers is essential.

4. Filler colour according to the finish colour

Do not use one type of filler colour per system, but rather adapt it according to the shade of the three-coat finish to be applied.

Thus, in a white three-coat colour we always recommend using a white filler. In dark three-coat colours we recommend using a black or grey filler.

The main reason is that the three-coat colour applied on a similar shade of filler will require fewer layers to achieve good opacity and coverage. This will minimise the risk of obtaining an incorrect colour match or possible painting defects such as gloss loss.

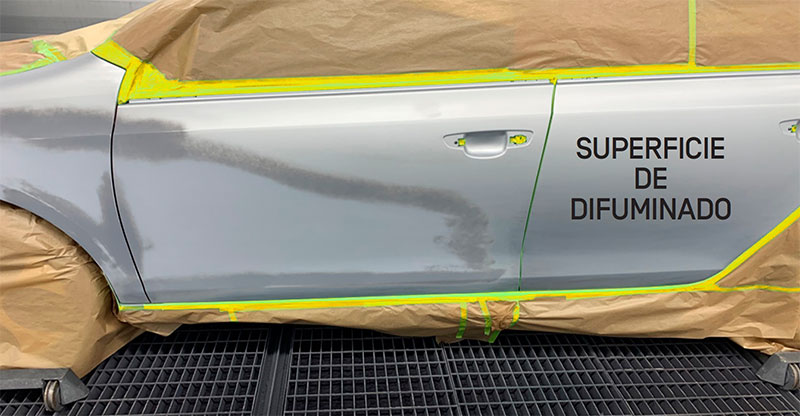

5. Application of three-coat colours with blending

After testing the colours on the paint test cards and choosing one of the versions, apply the colour on the surface to repair.

As noted earlier, the possible differences in distance and speed of application and the coat thickness are factors that can lead to colour differences.

Therefore, in three-coat finishes, a recommended practice is to apply the product using the blending technique to minimise any possible matching error or colour leap, especially between parts and adjacent areas.

This type is also recommended for basecoat finishes, with the exception that in a three-coat colour both the base and the effect coats must be blended.

When blending both coats, more space will be needed for a subtle blending, so you will use adjacent areas more often than in other finishes.

Conclusion

As we have seen, three-coat finishes are undoubtedly more complex than other types of finish.

However, if you follow the paint manufacturer’s technical data sheet and follow the times for each process, any experienced professional will be able to obtain high-level colour matching results when faced with a three-coat colour repair.

Mastering its application will also have an impact on the bodyshop’s profitability, helping to increase productivity and efficiency.